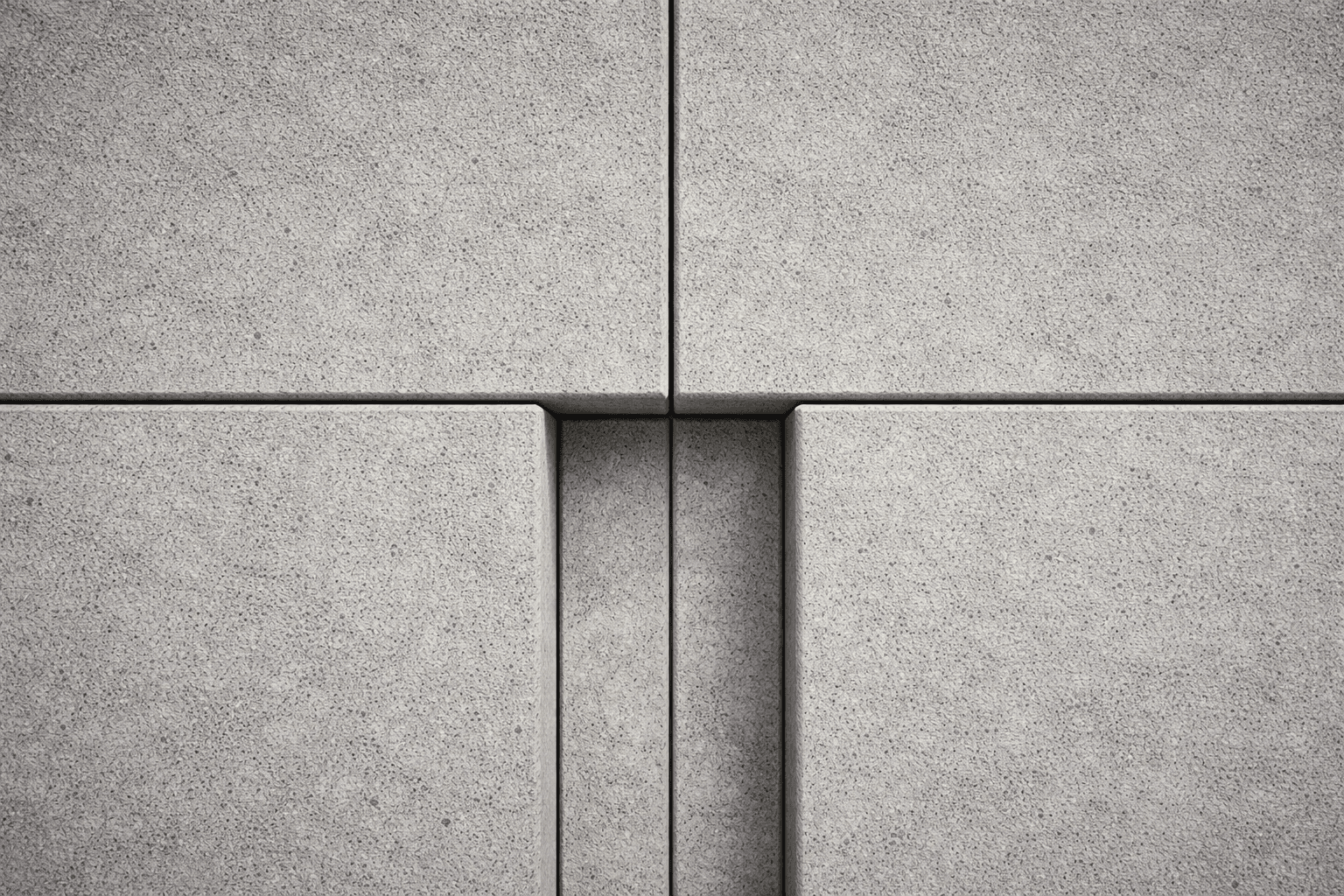

Plate VI — Precision

Structural intent

Show exactness through joinery, fit, alignment, and measured construction. Precision is evidenced by tight tolerances and repeatable geometry.

What must be observable

- Tight joints (stone blocks, tiles, metal seams) with minimal gaps.

- Straight edges and consistent angles.

- Evidence of measurement: uniform spacing, consistent module sizes.

- Clean intersections (corners, joints) that demonstrate controlled assembly.

Common failure modes

- “Clean-looking” surfaces without observable joints or alignment evidence.

- Decorative detail mistaken for precision (ornament ≠ tolerance).

- Lighting hides edges, making fit unverifiable.

- Perspective distortion that makes lines appear misaligned.

UI / system translation (non-symbolic)

- Use for settings, calibration, and verification screens.

- In UI: pixel-perfect alignment, baseline grids, consistent spacing scale.

- In system terms: validations, constraints, and schema-level enforcement.

- QA: require visible edges/joints; reject blurred/hidden tolerance cues.